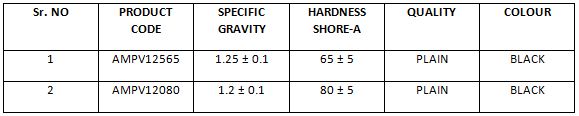

Neoprene Rubber Sheets

Neoprene Rubber Sheet is have excellent resistance to any kind of impact and abrasions and also has good elastic properties.These sheets exhibit unmatched mechanical strength, excellent flexibility, and second to none resistance to fire and high temperatures.

It shows good resistance to any petroleum based oils and fuel, and thus makes it perfect for sealing and isolating applications. They also have excellent anti-vibration properties. They are even stable when exposed to UV rays and are resistant to the harmful effects of ozone, and extreme weather conditions.

These sheets have outstanding adhesion properties to metal surfaces and is available in a variety of choices depending on specific gravity, hardness, chloroprene content, mechanical properties and surface finish as well.

They have an operating temperature range of -40 °C to +120 °C.

Applications:

- Anti-vibration strips pads,

- mounting pads

- sealing gaskets/ packings for hot air,

- water and gases requiring moderate oil resistance

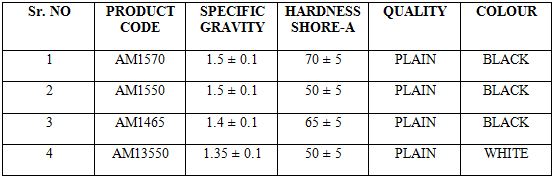

Natural Rubber Sheet

AHMEDBAD MOULDS Rubber manufactures a comprehensive range of rubber sheeting. From basic commercial compounds to highly technical sheets to match stringent customer specifications. Rubber Sheet highly innovative team also offers development of custom compounds for our customers.

Applications:

- sealing gaskets for joints in connections of air/water/gases pipelines and valves

- Anti-vibration pads and for general insulation as well as packing purpose.

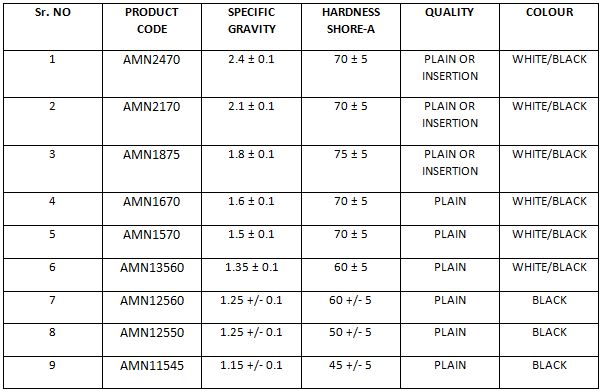

Silicone Rubber Sheets

Silicone Rubber Sheet stands out from other polymers as they are extremely non-toxic, flexible, inert, light weight, and resistant to very high temperatures and weather.

Silicone Rubber Sheets exhibit excellent resistance and stability when exposed to UV rays and also towards the harmful effects of ozone. It also exhibits outstanding resistance to weather conditions and has good physical properties and can maintain its flexibility even under extreme temperatures.

Silicon sheets are non-conductive in nature and have a high dielectric strength making them suitable for critical electrical and electronic insulating and isolating applications.

They are also resistant to oils and greases, acids, alkalis and are available in a large variety depending on hardness, specific gravity, color, physical properties & surface finish.

Silicon Sheets have an operating temperature range of -55 °C to +245 °C

Applications:

- Due to its non-toxicity combined with its resistance to temperature and chemicals, it is extensively used in the food and pharma industry. It is also used for packing and sealing in applications where high temperature resistance is required.

- It’s non-conductive nature along with its resistance to extreme weather conditions, ensures its use in electrical insulation applications, which are also open to weather. It is also finds use in electrical and lighting fixtures as well as heat resistant expansion joints.

- Due to its non-toxic and hypo-allergic nature it is also used in baby and infant products and applications.

- Used to make sealing gaskets for joints in connections of air/water/gases pipelines and valves. Also used as anti-viberation pads and for general insulation

Conductive Rubber Sheets

The rubber is made conductive by incorporating small conductive metal particles throughout the material. It can provide an EMI-proof and watertight seal in narrow constructions. Electrically conductive rubbers are typically used for EMI applications. But they are also useful for EMP protection, wave-guide applications and against static electricity. The rubber can be filled with silver, nickel, silvered glass, silvered aluminium, or graphite (only for ESD). Commercial EMI applications often choose Nickel-graphite conductive rubber or Graphite conductive rubber from a costs point of view, while military and aerospace applications often call for Silver copper silicone conductive rubber to meet Mil-G-83528C specifications. In military or aerospace, fluoro-silicone versions may also be used due to their chemical and fuel resistance.

Features:

- Excellent conductivity on the entire surface

- Excellent electromagnetic shielding effect

- Easy die-cutting, kiss-cutting, and slitting

PVC Rubber Sheets

PVC Rubber sheets are made from a blend of PVC and Acrylonitrile Butadiene Rubber.

Due to the blend, the excellent oil and gas resistance of nitrile rubber sheets, is complemented by the weather resistance of PVC. These sheets have a very good oil and grease resistance and good weather and flame resistance due to PVC.

They have an operating temperature range of – 20°c to 120°c

Applications:

- oil resistance is required along with weather resistance